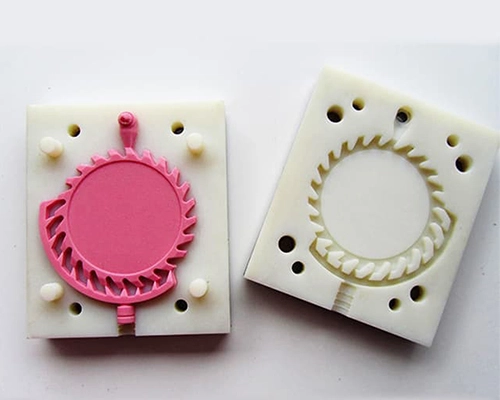

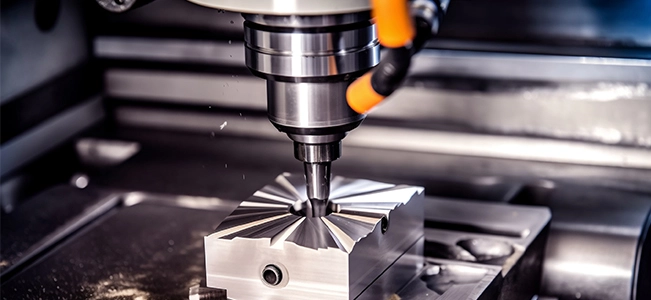

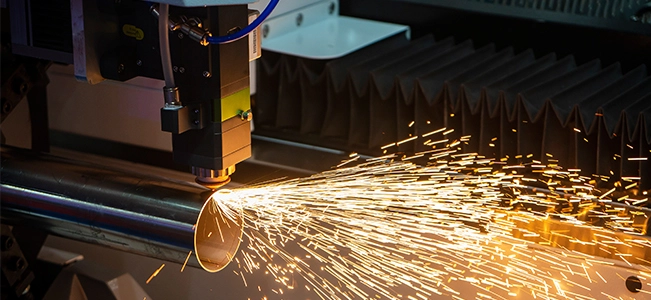

As a leading provider of vacuum casting services, our state-of-the-art vacuum casting factory delivers high-quality prototypes and end-use parts with precision and fast turnaround. Specializing in vacuum casting prototyping, we replicate complex geometries with fine details, ideal for functional testing and low-volume production. Our expertise as a reliable vacuum casting manufacturer ensures durable vacuum casting machine parts for automotive, aerospace, medical, and consumer electronics industries. We offer a wide selection of vacuum casting materials, including ABS-like, PP-like, high-temperature-resistant, and flexible resins, tailored to mimic final production materials. From rapid silicone mold fabrication to post-processing (painting, plating, texture finishing), our vacuum casting services streamline product development with cost-effective, high-fidelity solutions. Whether you need functional prototypes, small-batch production, or bridge manufacturing, trust our vacuum casting factory to accelerate your time-to-market.

English

English  中文

中文  日本語

日本語  한국어

한국어