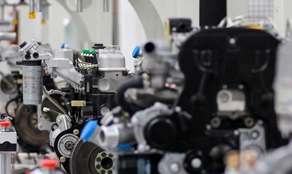

As a renowned manufacturing factory in China, Flourish Legend takes pride in its advanced equipment and professional technical talent. Our physical CNC machining factory specializes in the customized processing of "titanium" ultra-precision complex structural components. Whatever type of parts you require, we can provide the perfect solutions. Our craftsmanship and engineering capabilities are unparalleled in the industry, ensuring you receive the highest quality products. By choosing Flourish Legend, you will experience unmatched precision, quick delivery, and exceptional customer service.

| Items | Descriptions |

| Machinability and General Principles of Titanium Alloys Cutting | Titanium alloys are categorized into different phases, namely the alpha phase (TA), beta phase (TB), and alpha-beta phase (TC), based on their metallographic structure The TA series is generally used for castings and forgings, while the TC series is used for bar stock. |

| Characteristics and Machinability | High strength-to-weight ratio: With a density of only 4.5g/cm³, titanium alloys are much lighter than iron but possess strength similar to that of ordinary carbon steel. |

| Excellent mechanical properties: Titanium alloys have a high melting point of 1660°C, higher than that of iron. They exhibit good heat resistance, work well below 550°C, and display good toughness at low temperatures. | |

| Outstanding corrosion resistance: Titanium alloys readily form a dense oxide film on their surfaces below 550°C, which prevents further oxidation. This feature grants them high corrosion resistance against atmospheric conditions, seawater, steam, and various acids, alkalis, and salt medium | |

| Titanium Alloys Have Poor Machinability Due To Several Reasons: | Poor thermal conductivity leads to high cutting temperatures that reduce tool durability. |

| Oxidation and the formation of a hard oxide layer on the surface above 600°C, resulting in severe tool wear. | |

| Low plasticity and high hardness, causing increased shear angle, minimal contact length between chips and the rake face, and high-stress concentration on the rake face, making the tool edge prone to failure | |

| Low elastic modulus and significant elastic deformation, result in substantial spring-back at the workpiece surface close to the rake face, leading to extensive wear. | |

| The aforementioned characteristics of titanium alloys during cutting make machining challenging, resulting in low efficiency and high tool consumption. | |

| General Principles of Cutting Processes | Use carbide-cutting tools whenever possible Tungsten-cobalt carbide alloys exhibit minimal chemical affinity, good thermal conductivity, and high strength. Impact-resistant ultrafine-grain carbide alloys can be employed for intermittent cutting at low speeds, while high-speed steel with good high-temperature performance can be used for forming complex tools. |

| Employ smaller rake angles and larger clearance angles to increase the contact length between chips and the rake face, reduce friction with the workpiece on the clearance face, and use rounded cutting edges to improve strength and prevent edge burning and chipping. | |

| Maintain a sharp cutting edge to ensure smooth chip evacuation and avoid chip adhesion and chipping. | |

| Opt for low cutting speeds to prevent excessive cutting temperatures. Use moderate feed rates to avoid tool burning due to working in the hardened layer. Consider deeper cutting depths to allow the cutting edge to work below the hardened layer, thereby enhancing tool durability. | |

| Sufficient coolant should be applied during machining for proper cooling. | |

| Due to the high cutting resistance during titanium alloy cutting, the rigidity of the machining system needs to be ensured As titanium alloys are prone to deformation, the clamping force should not be excessive Auxiliary support may be used when necessary, particularly for precision machining operations. | |

| These are general principles to consider during titanium alloy machining. However, it is important to note that different custom metal machining methods and specific conditions may require focusing on different points of emphasis and addressing specific challenges. | |

| Processes | Descriptions | Advantages |

| Turning | Titanium alloy turning allows for achieving good surface roughness, with less severe work hardening. However, it leads to high cutting temperatures and rapid tool wear. To address these issues, the following measures are typically taken regarding tooling and cutting parameters: | Tool Material: Utilize YG6, YG8, or YG10HT cemented carbide, based on the available resources in the factory. |

| Tool Geometry: Optimize the rake and clearance angles, and apply rounded cutting edges. | ||

| Lower cutting speeds. | ||

| Moderate feed rates. | ||

| Deeper cutting depths. | ||

| Milling | Titanium alloy milling is more challenging than turning due to intermittent cutting and chip adhesion to the cutting edges. It often results in chip removal and significant tool wear upon subsequent engagement with the workpiece. For successful milling of titanium alloys, the following considerations are crucial | Reduce the rake angle and increase the clearance angle compared to standard milling tools. |

| Employ lower milling speeds. | ||

| Prefer the use of pointed milling cutters instead of flat-end mills. | ||

| Ensure a smooth transition of the cutting edges. | ||

| Apply ample cutting fluid. | ||

| To enhance productivity, increase the milling depth and width, typically ranging from 1.5 to 3.0mm for roughing and 0.2 to 0.5mm for finishing. | ||

| Grinding | Grinding titanium alloy parts often results in issues such as clogged grinding wheels due to chip adhesion and surface burning. These problems occur due to the poor thermal conductivity of titanium alloys, leading to high temperatures during grinding, causing adhesion, diffusion, and strong chemical reactions between titanium alloys and abrasive particles. Clogged wheels reduce the grinding ratio, and the diffusion and chemical reactions result in surface burning, leading to reduced fatigue strength, which is more evident when grinding titanium alloy castings. To address these problems, the following measures are implemented: | Select suitable grinding wheel materials such as green silicon carbide TL. |

| Opt for slightly softer grinding wheel hardness (ZR1). | ||

| Use coarser grit size wheels (60). | ||

| Lower grinding wheel speeds (10-20m/s). | ||

| Reduce the feed rate. | ||

| Ensure sufficient cooling with emulsion. | ||

| Drilling | Drilling titanium alloys is challenging, often resulting in tool burning and drill breakage. These issues are primarily caused by poor tool edge grinding, delayed chip evacuation, inadequate cooling, and poor rigidity of the process system. Therefore, the following points should be considered during titanium alloy drilling: | Tool material: Use high-speed steel M42, B201, or cemented carbide. |

| Proper drill edge grinding: Increase the point angle, reduce the front angle at the outer edge, and increase the back angle at the outer edge. The taper should be two to three times that of a standard drill. | ||

| Regular tool retraction and timely chip removal, paying attention to the shape and color of the chips. If feather-like chips or color changes occur during drilling, it indicates tool bluntness and regrinding or replacement should be done promptly. | ||

| Apply sufficient cutting fluid, such as soybean oil, with the option to add specific drilling and tapping oils when necessary. | ||

| Improve the rigidity of the processing system: Fix the drill on the worktable, ensure close proximity between the drill guide and the workpiece, and use short drills whenever possible. | ||

| Reaming | When reaming titanium alloys, tool wear is not severe, and both cemented carbide and high-speed steel reamers can be used. Commonly used types in factories include W18Cr4V, M42, YW1, YG8, YG10HT, etc. When using cemented carbide reamers, similar to drilling, attention should be paid to the rigidity of the machining system to prevent reamer chipping. The main problem encountered during titanium alloy reaming is uneven reamed holes, and the following solutions can be employed: | Narrow the width of the reamer blade with oil stone to prevent the blade from bonding with the hole wall, while ensuring sufficient strength. Generally, a blade width of 0.1-0.15mm is preferable. |

| The transition between the cutting edge and the calibration section should be a smooth arc, and it should be promptly reshaped and maintained to ensure consistent arc sizes for each tooth. | ||

| If necessary, increase the reverse taper of the calibration section. | ||

| Perform reaming in two stages, with a rough reaming allowance of 0.1mm and a fine reaming allowance generally less than 0.05mm. | ||

| Spindle speed: 60r/min. | ||

| When retracting the reamer after reaming, manual reaming should not be reversed, and machine reaming should be retracted without stopping the machine. | ||

| Tapping | Tapping titanium alloys, especially small hole tapping below M6mm, is quite challenging. This is mainly due to the fine chips that easily adhere to the cutting edges and the workpiece, resulting in high surface roughness values and increased torque. Improper selection and handling of tap tools can lead to work hardening, low processing efficiency, and even tap breakage. The following solutions can be implemented: | Preferably use jump-thread taps that fit snugly. The number of teeth should be fewer than standard taps, typically 2-3 teeth. The cutting cone angle should be large, and the taper part should generally be 3-4 times the pitch length. To facilitate chip removal, a negative rake angle can be ground on the cutting cone section. Short taps should be used whenever possible to increase tap rigidity. The reverse taper part of the tap should be appropriately enlarged compared to the standard tap to reduce friction between the tap and the workpiece. |

| When machining the threaded bottom hole, drill a rough hole first and then use a reaming drill to enlarge the hole to reduce the work hardening of the bottom hole. For threads with a pitch of 0.7-1.5mm, the bottom hole size can be machined to the upper limit of the standard threaded bottom hole specified by the national standard, allowing an additional increase of 0.1mm. | ||

| If not limited by the thread hole position and the shape of the workpiece, machine tapping should be preferred to avoid work hardening caused by uneven manual tapping feed or interruptions. |

The above information provides fundamental knowledge about titanium and titanium alloy machining. If you have any requirements for customized titanium machining parts, feel free to contact Flourish Legend at any time.

| - | Process | Turning tool rake angle | Lathe Angle | Tool nose radius | Cutting speed | Depth of cut feed |

| Rough car | 5 | 6~10° | 1~2° | 40 | 3m/min | 0.2~0.3fmm/r |

| Fine car | 5 | 6~10° | 0.5° | 60 | 0.2~0.5m/min | 0.1fmm/r |

Titanium and titanium alloy standard parts, commonly known as the ""rice of industry,"" are widely used in various industries, including:

As a renowned manufacturing factory in China, Flourish Legend takes pride in its advanced equipment and professional technical talent. Our physical CNC machining factory specializes in the customized processing of "titanium" ultra-precision complex structural components. Whatever type of parts you require, we can provide the perfect solutions. Our craftsmanship and engineering capabilities are unparalleled in the industry, ensuring you receive the highest quality products. By choosing Flourish Legend, you will experience unmatched precision, quick delivery, and exceptional customer service.

High Precision Machining: By combining CNC technology with advanced equipment, precision CNC machining of titanium alloys can be achieved. Through precise calculation and control, micron-level accuracy can be achieved to ensure that machined parts meet strict dimensional and geometric requirements.

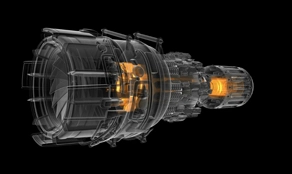

Complex Structure Machining: Titanium alloys are commonly used in the manufacturing of complex structural components, such as aerospace parts and medical devices. CNC machining, with its multi-axis control like 5 axis machining and complex tool path planning, can accurately machine various shapes and holes in complex titanium alloy structures, meeting the manufacturing requirements of intricate parts.

High Production Efficiency: CNC machining is characterized by automation and high efficiency. Once the program is written, it can run continuously to produce multiple identical or similar parts, greatly improving production efficiency. Additionally, CNC machining allows for the integration of multiple processing steps, reducing manual intervention and enhancing production efficiency and consistency.

The surface quality of titanium alloys is crucial for many applications, such as the biocompatibility of medical devices and the aerodynamic performance of aerospace components. CNC machining can achieve high-quality surface finishes for titanium alloy parts by optimizing tool selection, employing appropriate cutting parameters, and utilizing surface treatment techniques to meet various stringent surface requirements.

ISO International Quality Management System

Equipped with ISO 9001 certificate, we are able to support your OEM/ODM production.

Quality Control

We will check color, appearnce and tolerance by qulity control at every step during manufacturing process.

Low & High Volume Manufacturing

Besides high-volume production, we can also provide good solutions for your low-volume production (MOQ》1) with prototyping process.

Competitive Price

Our continuous investments in equipment and QC systems help us to get higher efficiency and quality which decrease reject ratio and increase market competitiveness in delivery qualified parts on time.

Reliability and Stability

Our 24 hours | 3 shifts production systems help your parts get into markets quickly and steadily.