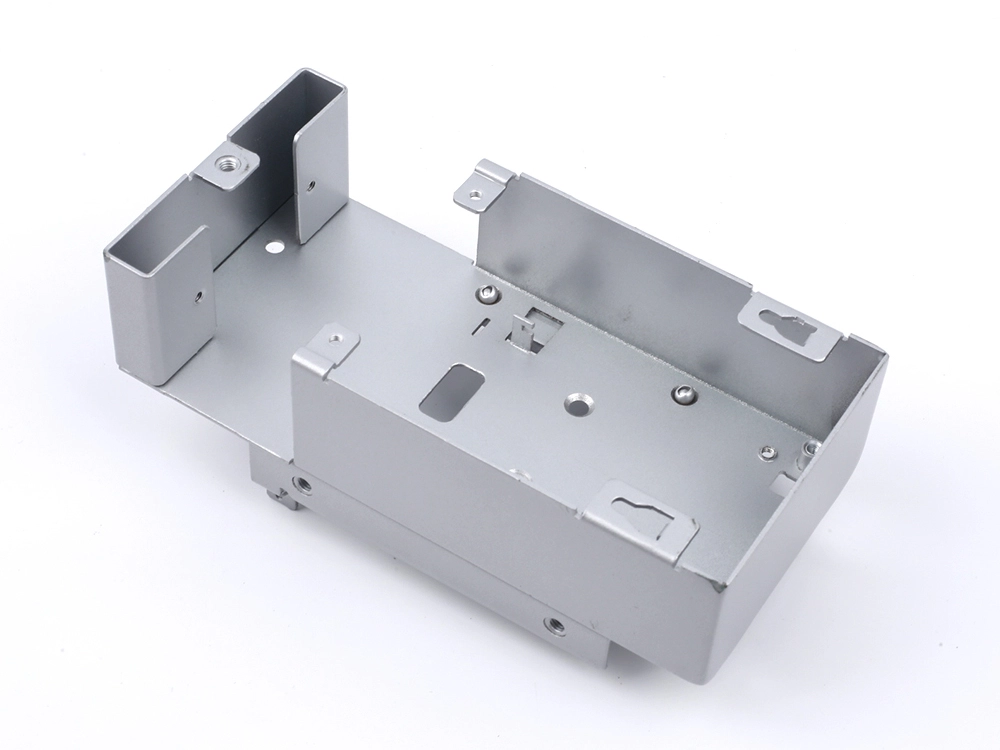

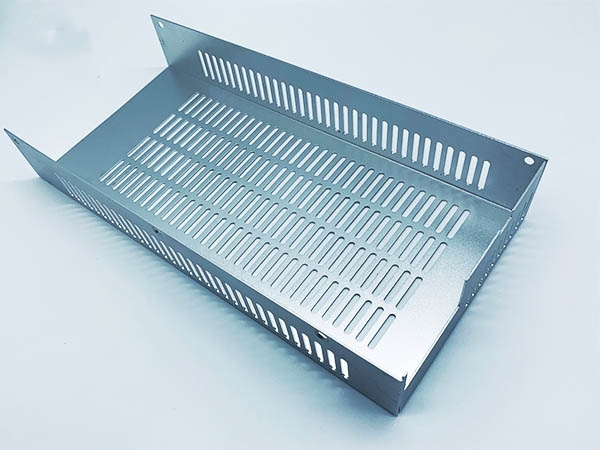

Flourish Legend is your reliable partner for custom metal stamping services. With years of experience and excellent technical capabilities, we provide high-quality and efficient customized solutions in the field of custom metal stamping. Through advanced customized metal stamping equipment and processes, we can quickly and accurately shape metal sheets into the desired shapes and sizes, including cutting, bending, punching, and forming operations.

We focus on quality control and strict inspection procedures and advanced measuring equipment to ensure the precision and reliability of each product. Whether you are in the electronics, medical, automotive, machinery manufacturing, or other industries, we, a professional precision metal stamping company, are committed to meeting your needs with high-quality custom metal stamping services and competitive prices, and establishing long-term partnerships with you.

FlourishLegend custom metal stamping process is divided into four key processes

1. Cutting

Shearing is the most basic processing method in the stamping process. It divides the sheet into lengthwise segments as needed. In shearing, a cutting die is used to separate the sheet into parts of the required length.

2. Punching

Punching is a processing method in the stamping process. It passes the plate through a punching die to drill the required holes in the material. Punching presses a part of the material into the mold by rapidly impacting the mold to form the required hole. In practical applications, punching can be used to make various parts, such as key holes, screw holes, positioning holes, etc. During the punching operation, the size and location of the holes need to be considered to ensure the rationality of the parts.

3. Bending

Bending: In the bending step, the metal material is precisely bent into the required angle and shape by special equipment to meet specific design requirements. For large-volume production orders, such as our wholesale brass stampings, this process ensures that the bending angle and shape of each part are exactly the same to ensure product quality and performance. In practical applications, bending can be used to make parts of various shapes, including angle steel, U-shaped pipes, L-shaped plates, etc. In the bending process, a suitable mold needs to be designed according to the shape of the part to ensure the accuracy and performance of the final product.

4. Deep drawing

Deep drawing is a processing method in the precision metal stamping process. It processes flat materials into parts with longer depth as required. During the deep drawing process, the material needs to be stretched into the required shape through a forming die.

In practical applications, deep drawing can be used to make cylindrical parts of various shapes, such as automobile fuel tanks, chimneys, pipes, etc. In the deep drawing process, it is necessary to control the deformation and stress of the material by adjusting the design of the mold and the processing parameters of the material to ensure the quality and performance of the final product.

5. What are the advantages of FlourishLegend’s customized metal stamping?

High production efficiency, easy operation, high material utilization, good surface quality and low cost.

Stamping process is one of the commonly used processing methods in the manufacturing industry. Shearing, punching, bending and drawing are the four basic processes in the stamping process. In practical applications, these four basic processes can process parts of various shapes by adjusting the design of the forming mold and material processing parameters. By learning and mastering these basic processes, the production efficiency of the stamping process and the quality of the product can be improved.

Custom metal stamping is a common manufacturing process. Also known simply as customized metal stamping, it involves the use of a precision metal stamping machine to deform and shape a metal workpiece. Metal workpieces usually consist of metal plates like copper stamping dies. To change the shape of a sheet of metal, a manufacturing company can stamp it. How exactly does metal stamping work?

Basic knowledge of custom metal stamping

Although it sounds complicated, precision metal stamping is a relatively simple manufacturing process. It requires the use of a stamping machine to deform and shape metal workpieces. Stamping presses are heavy-duty machines that basically sandwich a metal workpiece between a set of dies. They usually have one mold on the top and another mold on the bottom.

During use, the punch press presses the upper die down onto the lower die. Since the metal workpiece is placed between these two molds, it will take on their respective shapes. The base of the metal workpiece will take the shape of the counter mold. On the other hand, the top of the metal workpiece will take the shape of the upper die.

On-time Delivery: Our intelligent collaborative manufacturing system and a team of 100+ engineers enable real-time tracking of production progress to ensure on-time delivery.

High Quality: All finished products undergo 100% quality inspection before delivery to ensure that each item meets the customer's requirements.

Excellent Service: From quotation to order placement, production, delivery, quality inspection, and logistics, the entire process is visualized, providing exclusive 1V1 custom metal stamping services, including brass stampings wholesale and China stainless steel stamping.

Competitive Prices: As a leading custom metal stamping company, we offer the lowest prices in the industry, reducing your production costs.

Custom metal stamping is a common metal processing method used to manufacture a variety of metal parts. Common precision metal stamping materials are steel, copper, aluminum, etc.

ISO International Quality Management System

Equipped with ISO 9001 certificate, we are able to support your OEM/ODM production.

Quality Control

We will check color, appearnce and tolerance by qulity control at every step during manufacturing process.

Low & High Volume Manufacturing

Besides high-volume production, we can also provide good solutions for your low-volume production (MOQ》1) with prototyping process.

Competitive Price

Our continuous investments in equipment and QC systems help us to get higher efficiency and quality which decrease reject ratio and increase market competitiveness in delivery qualified parts on time.

Reliability and Stability

Our 24 hours | 3 shifts production systems help your parts get into markets quickly and steadily.