Flourish Legend is your trusted partner for stamping services. With years of experience and excellent technical capabilities, we provide efficient customized solutions in the field of stamping. Through advanced stamping equipment and processes, we can quickly and accurately cut, bend, punch, and form metal sheets such as steel, aluminum, stainless steel, copper, galvanized steel, and alloy steel.

Our goal is to create the desired shapes and dimensions. Quality control is paramount to us, and we adhere to strict inspection procedures and utilize advanced measurement equipment to ensure the precision and reliability of every product.

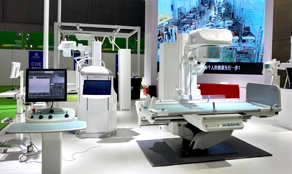

Whether you are in the electronics, medical, automotive, mechanical manufacturing, or other industries, we are dedicated to meeting your needs with high-quality service and competitive prices. We strive to establish long-term partnerships by delivering exceptional service and creating value for our customers.

Flourish Legend - your reliable partner for efficient and customized stamping solutions.

Stamping commonly involves the use of the following materials, each with its own characteristic properties:

| Materials | Descriptions |

| Cold Rolled Steel | High Strength: Cold rolled steel exhibits high strength, suitable for parts that require high loads and structural stability. |

| Good Formability: Cold rolled steel is easy to stamp and form, allowing the manufacturing of various shaped parts. | |

| Good Surface Quality: Cold rolled steel has a smooth surface, suitable for parts that require high surface quality and coatings/paints. | |

| Stainless Steel | Excellent Corrosion Resistance: Stainless steel has excellent corrosion resistance, capable of withstanding corrosion from oxidation, acids, and alkalis. |

| High-Temperature Performance: Certain stainless steel alloys possess good high-temperature stability and oxidation resistance, suitable for applications in high-temperature environments. | |

| High Strength and Hardness: Stamped stainless steel offers high strength and hardness, making it suitable for applications that require strength and wear resistance. | |

| Aluminum | Lightweight: Aluminum has a low density, making it an ideal choice for manufacturing lightweight products such as automotive and aerospace components. |

| Good Corrosion Resistance: Aluminum exhibits good corrosion resistance and can be used in environments with higher humidity without being easily damaged. | |

| Good Thermal Conductivity: Aluminum has excellent thermal conductivity, making it suitable for aluminum stamping parts with high heat dissipation requirements, such as heat sinks. | |

| Copper | Good Electrical Conductivity: Copper has excellent electrical conductivity, suitable for manufacturing parts that require good electrical conductivity, such as electronic connectors and wires. |

| Good Thermal Conductivity: Copper possesses good thermal conductivity, useful for stamped copper sheets that require efficient heat dissipation. | |

| Good Corrosion Resistance: Copper has good corrosion resistance and can be used for an extended period in certain corrosive environments without significant corrosion. | |

| Galvanized Steel | Excellent Corrosion Resistance: The galvanized coating provides excellent corrosion resistance, allowing galvanized steel to withstand harsh environmental conditions without significant corrosion. |

| Good Decorative Surface: Galvanized steel has a bright surface, providing good decorative properties and appearance. |

When selecting stamping materials, it is essential to consider the characteristic properties of these materials and choose the most suitable one based on the requirements and application scenarios of the parts.

Stamping is a process in which metal materials are plastically deformed under the action of a mold by applying pressure. The stamping process usually includes punching, bending, forming, stretching, punching and other operations.

Flourish Legend is your trusted partner for stamping services. With years of experience and excellent technical capabilities, we provide efficient customized solutions in the field of stamping. Through advanced stamping equipment and processes, we can quickly and accurately cut, bend, punch, and form metal sheets such as steel, aluminum, stainless steel, copper, galvanized steel, and alloy steel.

Our goal is to create the desired shapes and dimensions. Quality control is paramount to us, and we adhere to strict inspection procedures and utilize advanced measurement equipment to ensure the precision and reliability of every product.

Whether you are in the electronics, medical, automotive, mechanical manufacturing, or other industries, we are dedicated to meeting your needs with high-quality service and competitive prices. We strive to establish long-term partnerships by delivering exceptional service and creating value for our customers.

Flourish Legend - your reliable partner for efficient and customized stamping solutions.

Efficiency and Cost-effectiveness: Stamping process offers high efficiency and fast production rates. Once the stamping dies are fabricated, large quantities of parts can be rapidly produced through continuous automated stamping. This makes stamping an ideal choice for mass production, enhancing production efficiency, and reducing costs.

Capability to Process Complex Shapes: Stamping process can handle complex-shaped metal parts. By using stamping dies with different shapes, various deformations like deep drawing, bending, stretching, and punching can be achieved. This allows stamping to meet the shape requirements of diverse products, providing greater design flexibility.

High Precision and Consistency: Stamping process demonstrates high precision and repeatability. With precisely designed and manufactured stamping dies, parts with precise shapes and consistent dimensions can be produced. This makes stamping well-suited for applications requiring high precision and consistency, such as the automotive industry and electronic devices.

Material Efficiency and Sustainability: The stamping process enables efficient utilization of raw materials and reduces waste. Since stamping typically requires a smaller area of raw material to manufacture parts, material waste can be minimized to a great extent. Additionally, the stamping process allows for the recycling and reuse of scrap materials, promoting sustainability. These advantages of the stamping process contribute to its efficiency, precision, flexibility, and sustainability.

ISO International Quality Management System

Equipped with ISO 9001 certificate, we are able to support your OEM/ODM production.

Quality Control

We will check color, appearnce and tolerance by qulity control at every step during manufacturing process.

Low & High Volume Manufacturing

Besides high-volume production, we can also provide good solutions for your low-volume production (MOQ》1) with prototyping process.

Competitive Price

Our continuous investments in equipment and QC systems help us to get higher efficiency and quality which decrease reject ratio and increase market competitiveness in delivery qualified parts on time.

Reliability and Stability

Our 24 hours | 3 shifts production systems help your parts get into markets quickly and steadily.