Search Result

-

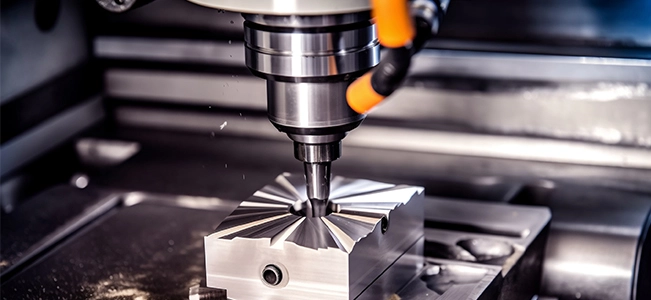

How to Calculate CNC Prototyping Cost?

08 05,2025

Prototyping with CNC machining is a crucial step in product development—but understanding its cost structure can be challenging. Many engineers and startups struggle to estimate expenses accurately, ...

How to Calculate CNC Prototyping Cost?

08 05,2025

Prototyping with CNC machining is a crucial step in product development—but understanding its cost structure can be challenging. Many engineers and startups struggle to estimate expenses accurately, ...

-

Vacuum Casting vs Vacuum Forming: How to Choose the Right Prototyping Method?

08 05,2025

When developing a new product, selecting the right prototyping process can mean the difference between smooth progress and costly redesigns. Two commonly confused methods—Vacuum Casting and Vacuum Fo...

Vacuum Casting vs Vacuum Forming: How to Choose the Right Prototyping Method?

08 05,2025

When developing a new product, selecting the right prototyping process can mean the difference between smooth progress and costly redesigns. Two commonly confused methods—Vacuum Casting and Vacuum Fo...

-

The Evolution of ABS Plastic Machining: Precision Meets Performance

10 30,2025

The Evolution of ABS Plastic Machining: Precision Meets PerformanceAs industries demand more precision, speed, and material efficiency, ABS plastic machining has become a cornerstone technology for mo...

The Evolution of ABS Plastic Machining: Precision Meets Performance

10 30,2025

The Evolution of ABS Plastic Machining: Precision Meets PerformanceAs industries demand more precision, speed, and material efficiency, ABS plastic machining has become a cornerstone technology for mo...

-

CNC Milling ABS Plastic: Accelerating Innovation in Product Development

10 29,2025

In the age of digital manufacturing, the ability to translate design concepts into real, functional components quickly and accurately defines industrial competitiveness. ABS CNC machining offers that ...

CNC Milling ABS Plastic: Accelerating Innovation in Product Development

10 29,2025

In the age of digital manufacturing, the ability to translate design concepts into real, functional components quickly and accurately defines industrial competitiveness. ABS CNC machining offers that ...

-

How Does MC Nylon Compare to Delrin in CNC Applications?

11 27,2025

MC Nylon generally offers better impact resistance and wear properties than Delrin in CNC applications, though Delrin excels in dimensional stability and lower moisture absorption, making the choice d...

How Does MC Nylon Compare to Delrin in CNC Applications?

11 27,2025

MC Nylon generally offers better impact resistance and wear properties than Delrin in CNC applications, though Delrin excels in dimensional stability and lower moisture absorption, making the choice d...

-

What Are the Latest Trends in Brass Stamping for 2025?

11 27,2025

The latest trends in brass stamping for 2025 include the adoption of advanced alloys for enhanced strength in automotive applications, increased automation for precision and efficiency, and a focus on...

What Are the Latest Trends in Brass Stamping for 2025?

11 27,2025

The latest trends in brass stamping for 2025 include the adoption of advanced alloys for enhanced strength in automotive applications, increased automation for precision and efficiency, and a focus on...

-

How Can Brass Stamping Parts Enhance Your Product Design?

11 27,2025

Brass stamping parts can enhance your product design by providing corrosion-resistant, conductive, and malleable components that offer tight tolerances, aesthetic appeal, and cost-effective scalabilit...

How Can Brass Stamping Parts Enhance Your Product Design?

11 27,2025

Brass stamping parts can enhance your product design by providing corrosion-resistant, conductive, and malleable components that offer tight tolerances, aesthetic appeal, and cost-effective scalabilit...

-

What is the CNC Machine

02 25,2026

Introduction: In the world of precision manufacturing, few technologies have had a more profound impact than the CNC (Computer Numerical Control) machine. These remarkable machines serve as the backbo...

What is the CNC Machine

02 25,2026

Introduction: In the world of precision manufacturing, few technologies have had a more profound impact than the CNC (Computer Numerical Control) machine. These remarkable machines serve as the backbo...

-

What is PTFE Used For

02 26,2026

Introduction: In the world of manufacturing and design, precision is paramount, and one technology stands out for its ability to deliver unparalleled accuracy: CNC, or Computer Numerical Control. This...

What is PTFE Used For

02 26,2026

Introduction: In the world of manufacturing and design, precision is paramount, and one technology stands out for its ability to deliver unparalleled accuracy: CNC, or Computer Numerical Control. This...

-

Prototyping Stainless Steel Parts: Should You Choose a CNC Robot Router or a Machining Center?

02 27,2026

When your hardware project moves into the prototyping phase and those stainless steel parts on your drawing need to become a reality, a direct question arises: Which service provider should you choose...

Prototyping Stainless Steel Parts: Should You Choose a CNC Robot Router or a Machining Center?

02 27,2026

When your hardware project moves into the prototyping phase and those stainless steel parts on your drawing need to become a reality, a direct question arises: Which service provider should you choose...

-

Nylon vs Polycarbonate: Which One Should You Choose for Precision Parts?

02 28,2026

You've spent weeks perfecting your 3D model. The tolerances are set, the features are aligned, and you're ready to prototype. Then comes the question that stops every hardware engineer in thei...

Nylon vs Polycarbonate: Which One Should You Choose for Precision Parts?

02 28,2026

You've spent weeks perfecting your 3D model. The tolerances are set, the features are aligned, and you're ready to prototype. Then comes the question that stops every hardware engineer in thei...

-

MIG vs TIG: Which One Should You Choose for Thin Sheet Metal Welding?

03 01,2026

You have spent weeks perfecting a precision sheet metal chassis design, only for the supplier to ask a deceptively simple question: "Should we run this with MIG or TIG?" You pause, suddenly ...

MIG vs TIG: Which One Should You Choose for Thin Sheet Metal Welding?

03 01,2026

You have spent weeks perfecting a precision sheet metal chassis design, only for the supplier to ask a deceptively simple question: "Should we run this with MIG or TIG?" You pause, suddenly ...

-

Automotive Sheet Metal Repair with MIG Welding: A Practical Guide from Rust Removal to Final Grinding

03 02,2026

Have you ever found yourself in this situation? You finally bought that classic car you have been dreaming about, only to discover the fender has rusted through. You take it to a repair shop, and the ...

Automotive Sheet Metal Repair with MIG Welding: A Practical Guide from Rust Removal to Final Grinding

03 02,2026

Have you ever found yourself in this situation? You finally bought that classic car you have been dreaming about, only to discover the fender has rusted through. You take it to a repair shop, and the ...

-

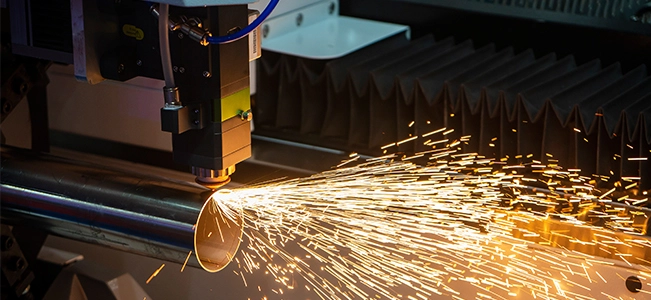

What Is Stamped Stainless Steel?

03 03,2026

You are designing a new product that requires a lot of metal parts—perhaps brackets, enclosures, or connectors. Your supplier asks: "Should we use stamping or machining?" You look at the dr...

What Is Stamped Stainless Steel?

03 03,2026

You are designing a new product that requires a lot of metal parts—perhaps brackets, enclosures, or connectors. Your supplier asks: "Should we use stamping or machining?" You look at the dr...

-

Automobile & Transportation

As a dedicated manufacturer of automotive and transportation industry components, we offer a wide range of component machining services. Whether it's engine parts, brake system components, chassis parts, or electrical equipment components, we provide high-quality components, delivering a one-stop solution for your automotive and transportation requirements.

Automobile & Transportation

As a dedicated manufacturer of automotive and transportation industry components, we offer a wide range of component machining services. Whether it's engine parts, brake system components, chassis parts, or electrical equipment components, we provide high-quality components, delivering a one-stop solution for your automotive and transportation requirements.

English

English  中文

中文  日本語

日本語  한국어

한국어