Sheet Metal Stamping - Trust Flourish Legend for Advanced Equipment, Comprehensive Project Management System, Defect-Free Products, Guaranteed Quality, Reasonable Pricing, and Long Product Lifespan. Welcome new and existing customers to customize your designs!

Technical Expertise: We have a highly experienced and knowledgeable team specializing in Sheet Metal Forming processes. Our technicians possess a wide range of skills and expertise, enabling them to provide innovative solutions tailored to meet the specific requirements of our customers. We ensure that our products meet high-quality forming standards.

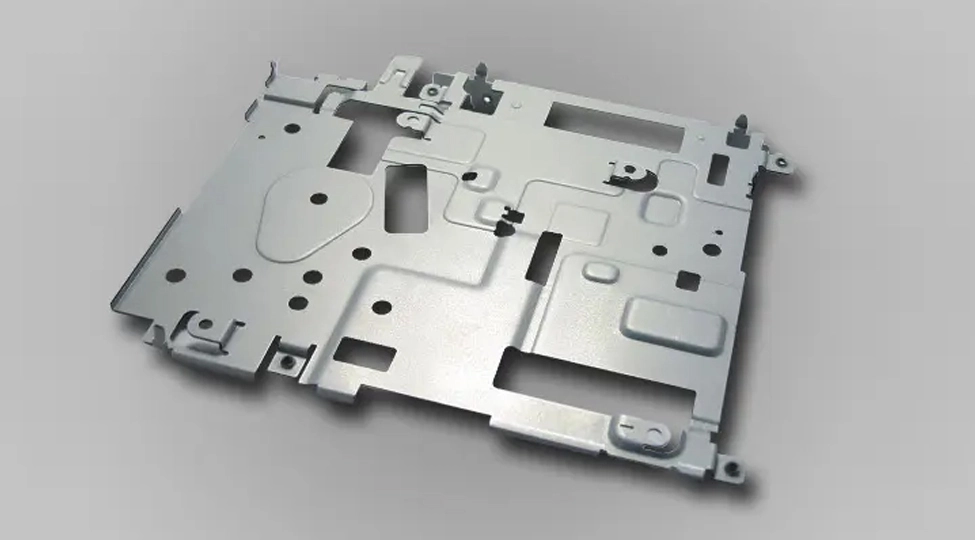

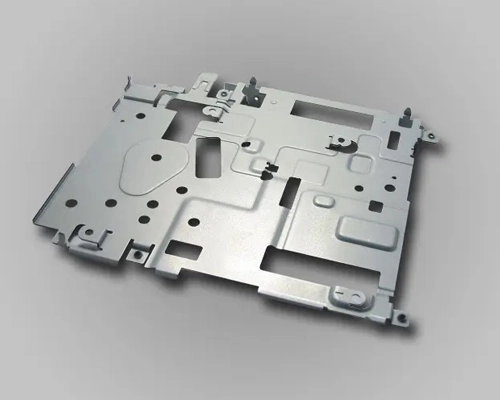

Advanced Equipment: We have invested in state-of-the-art Sheet Metal Forming equipment, including CNC punch presses, bending machines, and stamping machines. These advanced machines offer high precision and efficiency, guaranteeing accurate shaping of products and improved production efficiency.

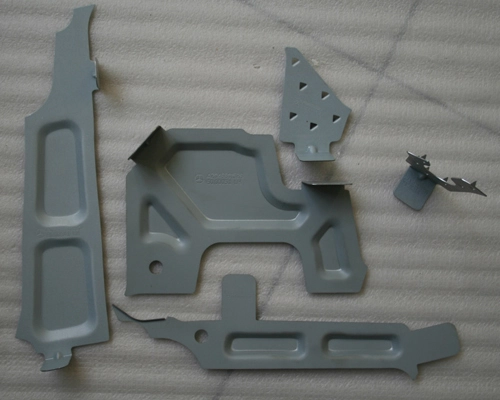

Customization Capability: We understand that every customer has unique needs, which is why we offer customized Sheet Metal Forming services. Our team can develop personalized process flows based on the client's design requirements and specifications, ensuring optimal forming results.

Quality Control: We prioritize quality control and adhere strictly to ISO standards and industry regulations. Our comprehensive quality management system includes rigorous inspection and testing procedures to ensure the stability and reliability of our products.

Prompt Delivery: Our efficient production process and flexible manufacturing capabilities enable us to deliver orders promptly. We optimize our production schedules and manage logistics effectively to ensure that customers receive their Sheet Metal Forming products in a timely manner, meeting their production needs."

High Precision Forming: Our Sheet Metal Forming service provides highly accurate shaping capabilities. We utilize advanced CNC equipment and precise techniques to ensure precise dimensions, shapes, and geometric features of the parts. Whether it's complex curved shapes or intricate details, we achieve high precision forming to meet customers' quality requirements.

Various Material: Our Sheet Metal Forming service accommodates various metal materials, including steel, aluminum, and stainless steel. We select the most suitable forming processes and parameters based on material characteristics and customer requirements, ensuring optimal strength, toughness, and surface quality. Whether it's thin or thick sheets, we can process and shape a wide range of materials.

Efficient Production: We prioritize production efficiency through optimized process flows and well-planned schedules. We minimize waste and downtime, maximizing production line utilization and capacity. Additionally, our flexible manufacturing capabilities allow us to quickly adjust and adapt to changing customer demands, ensuring on-time delivery.

Engineering Support: Our Sheet Metal Forming service extends beyond processing; we provide comprehensive engineering support. Our professional team brings extensive engineering experience and knowledge, offering expertise in design optimization, material selection, and process planning. This ensures the best forming results and production efficiency for our customers.

ISO International Quality Management System

Equipped with ISO 9001 certificate, we are able to support your OEM/ODM production.

Quality Control

We will check color, appearnce and tolerance by qulity control at every step during manufacturing process.

Low & High Volume Manufacturing

Besides high-volume production, we can also provide good solutions for your low-volume production (MOQ》1) with prototyping process.

Competitive Price

Our continuous investments in equipment and QC systems help us to get higher efficiency and quality which decrease reject ratio and increase market competitiveness in delivery qualified parts on time.

Reliability and Stability

Our 24 hours | 3 shifts production systems help your parts get into markets quickly and steadily.