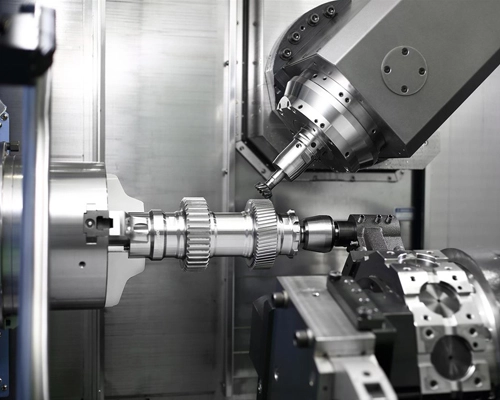

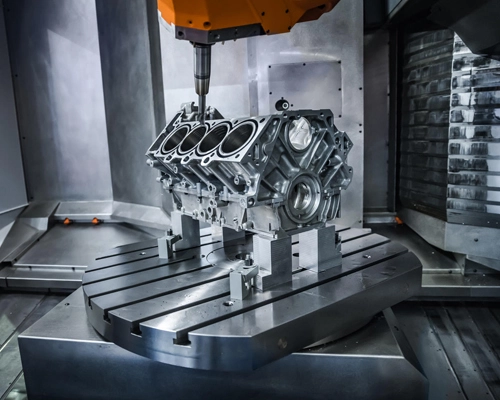

Flourish Legend is a CNC machining factory with decades of experience in metal and plastic milling. We specialize in CNC milling services including 2.5D milling, 3D milling, high-speed milling, multi-axis milling and high-efficiency milling. We emphasize in precision & quality for all customized solutions.

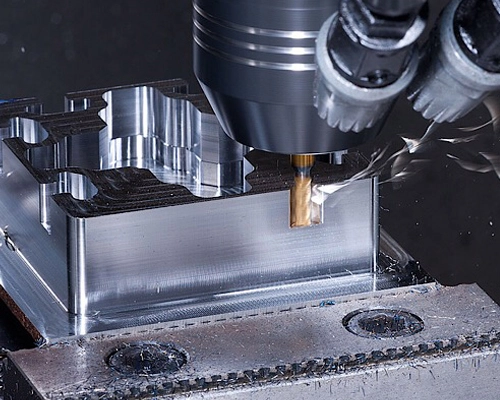

High Precision Machining: Our CNC milling services are equipped with high precision capabilities, ensuring accurate dimensional control and surface quality that meet our customers' precise requirements.

Versatility in Material Adaptability: Our CNC milling services are suitable for various materials, including metals, plastics, and composite materials. With extensive machining experience, we deliver high-quality milling for different material types.

Quick Turnaround Time: By employing efficient CNC milling processes and advanced equipment, we are able to complete machining tasks quickly. We are committed to on-time delivery to meet urgent customer needs and production schedules.

Customized Solutions: We provide customized CNC milling services, tailoring our solutions to the specific requirements and design drawings of our customers. Our technical team collaborates closely with clients to fulfill their unique machining needs.

Rigorous Quality Control: We strictly adhere to quality control standards throughout the entire machining process, including material selection, process monitoring, and final quality inspections. We ensure that every workpiece meets high-quality standards to guarantee customer satisfaction and product reliability.

Advanced Equipment and Technology: Equipped with state-of-the-art CNC milling machines and advanced numerical control technology, we achieve high-speed, high-precision, and efficient milling. We continuously invest in technology upgrades and equipment enhancements to stay at the forefront of the industry.

Complex Surface Machining: We excel in handling complex surface machining tasks. Through multi-axis milling and optimized tool path strategies, we achieve precise cutting of intricate shapes, curves, and profiles. Whether it's 3D carving, mold manufacturing, or aerospace component machining, we provide high-quality services.

CAD/CAM Integration: We integrate CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) into our workflow. This enables rapid conversion of design files into executable machining programs, facilitating highly automated production processes to enhance efficiency and accuracy.

Material Selection and Optimization: We are meticulous in material selection, optimizing it based on the characteristics and requirements of the workpiece. Collaborating with reliable suppliers, we ensure the use of high-quality materials and maximize their performance and efficiency through proper cutting parameters and process control.

Collaborative Teamwork: Our experienced team, consisting of engineers, operators, and quality control personnel, works closely together to ensure the successful completion of each project. We prioritize teamwork, communication, and coordination to deliver excellent services and solutions to our customers.

ISO International Quality Management System

Equipped with ISO 9001 certificate, we are able to support your OEM/ODM production.

Quality Control

We will check color, appearnce and tolerance by qulity control at every step during manufacturing process.

Low & High Volume Manufacturing

Besides high-volume production, we can also provide good solutions for your low-volume production (MOQ》1) with prototyping process.

Competitive Price

Our continuous investments in equipment and QC systems help us to get higher efficiency and quality which decrease reject ratio and increase market competitiveness in delivery qualified parts on time.

Reliability and Stability

Our 24 hours | 3 shifts production systems help your parts get into markets quickly and steadily.