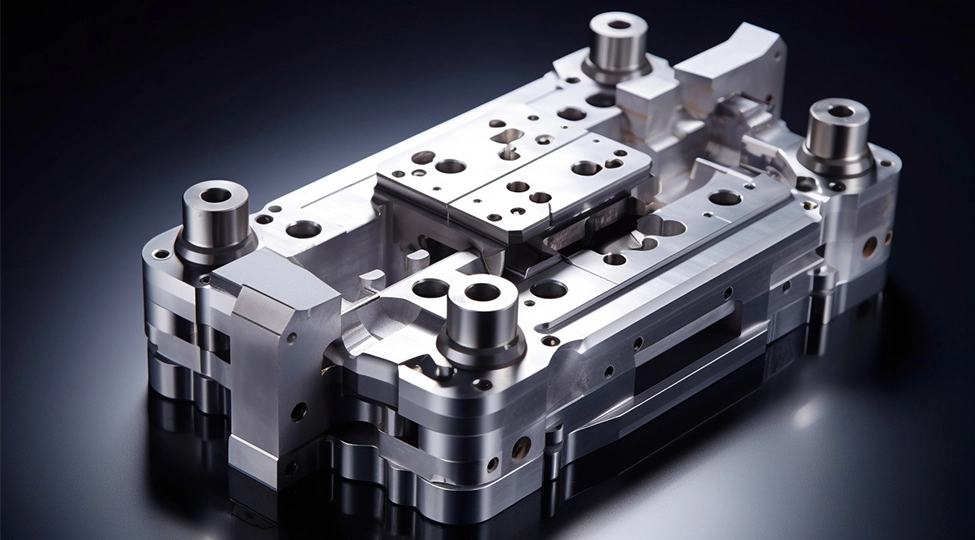

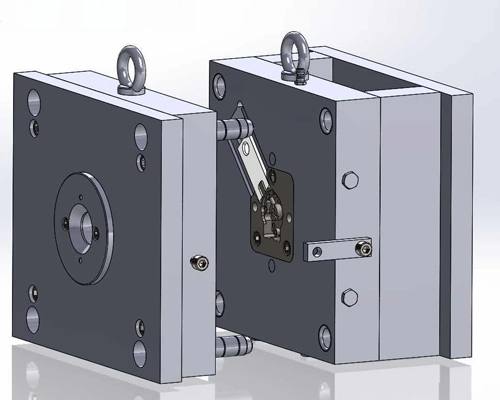

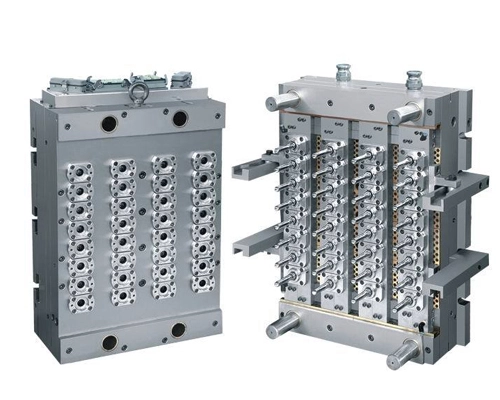

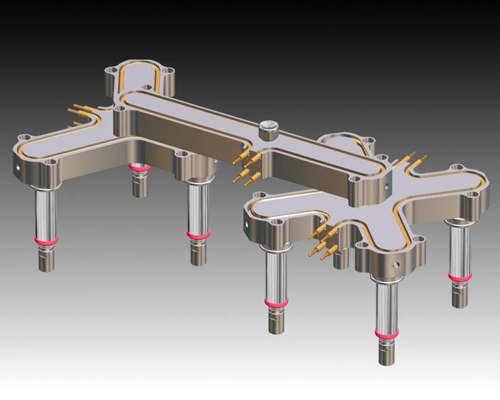

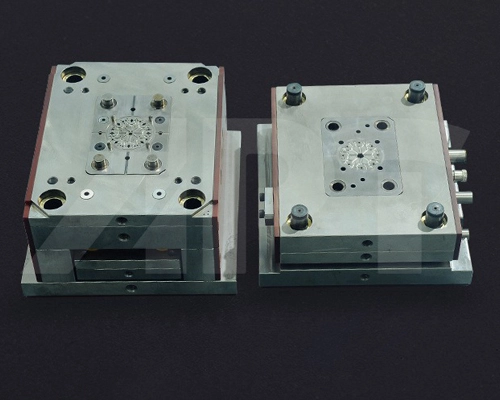

Flourish Legend is a professional manufacturer specializing in customized injection mold processing. We have a 1500-square-meter mold manufacturing workshop equipped with over 100 advanced imported mold manufacturing equipment. With a team of 50 professional mold designers, we provide one-stop injection mold solutions from mold design and manufacturing to product injection molding, assembly, and delivery. We offer customization for various types of molds including single-cavity, multi-cavity, hot runner, cold runner, variable core, sliding, and rotating molds.

Rich Experience: With years of experience in injection mold manufacturing, our team possesses extensive knowledge and skills to deliver high-quality injection mold services.

Customization Capability: We can customize injection molds according to the specific requirements and specifications of our customers, ensuring perfect compatibility between the mold and the product, thus enhancing production efficiency and quality.

Technological Innovation: We continually track and research injection mold manufacturing technologies, adopting the latest techniques and processes to provide efficient and reliable injection mold solutions.

Quality Assurance: We pay attention to every detail and strictly adhere to quality control standards, ensuring the precision, durability, and stability of our injection molds, thus providing reliable products to our customers.

Customer Support: We offer comprehensive customer support, including technical consultations and after-sales services, ensuring timely assistance and solutions throughout the injection mold manufacturing process.

High Precision Manufacturing: We employ advanced injection mold manufacturing equipment and precision machining techniques to ensure high-precision mold manufacturing, guaranteeing dimensional accuracy and meeting quality requirements.

Fast Delivery: With efficient production processes and flexible resource allocation, we can complete the manufacturing of injection molds in the shortest possible time to meet urgent delivery demands.

Material Adaptability: We have the capability to work with various injection molding materials, including plastics, rubber, etc. We can select the most suitable material according to customer requirements to achieve excellent injection molding results.

Cost-Effectiveness: We focus on process optimization and cost control, providing cost-effective injection mold solutions that help customers reduce production costs and enhance competitiveness.

Continuous Improvement: We are committed to continuous improvement and optimization of the injection mold manufacturing process. Leveraging advanced technologies and techniques, we improve production efficiency and mold lifespan, providing customers with better experiences and value.

ISO International Quality Management System

Equipped with ISO 9001 certificate, we are able to support your OEM/ODM production.

Quality Control

We will check color, appearnce and tolerance by qulity control at every step during manufacturing process.

Low & High Volume Manufacturing

Besides high-volume production, we can also provide good solutions for your low-volume production (MOQ》1) with prototyping process.

Competitive Price

Our continuous investments in equipment and QC systems help us to get higher efficiency and quality which decrease reject ratio and increase market competitiveness in delivery qualified parts on time.

Reliability and Stability

Our 24 hours | 3 shifts production systems help your parts get into markets quickly and steadily.