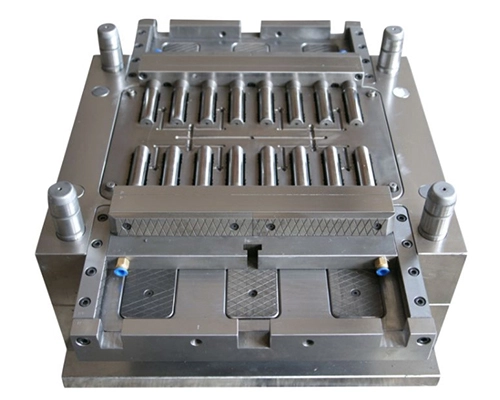

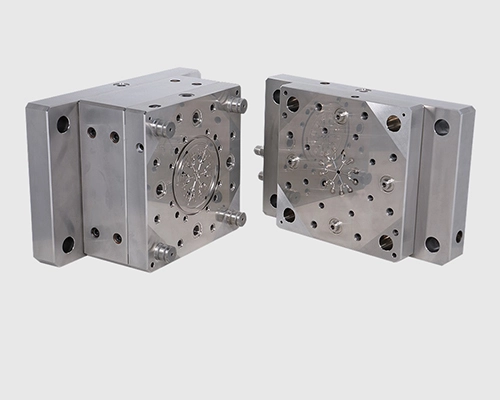

Flourish Legend stands out with its remarkable strength in the fields of mold manufacturing and injection molding. Leveraging years of experience and professional expertise, we offers high-quality custom mold manufacturing and injection molding solutions to worldwide clients. In the field of mold manufacturing, we have a skilled technical team capable of designing and fabricating molds of different shapes to meet various industries demands.

For injection molding, we have advanced equipment that achieve high precision and efficiency in production, ensuring good quality and timely delivery. Moreover, we prioritizes innovation and continuous improvement, consistently exploring new materials and technologies to provide clients with more choices and optimal solutions.

Top-notch Design Team: We have an experienced design team with extensive knowledge and professional skills in the mold manufacturing industry. They are familiar with various types of molds and application scenarios, capable of innovative design based on customer requirements, and provide efficient solutions combining best practices.

Advanced Design Software And Tools: We use advanced mold design software and tools such as CAD and CAM to ensure efficient and accurate design processes. These tools enable us to perform key steps such as 3D modeling, mold flow analysis, and collision detection, optimizing designs and improving production efficiency.

High-precision Manufacturing Equipment: We have advanced CNC machining equipment and high-precision machine tools for the processing of complex mold parts and precision machining. This automated equipment can accurately control product precision, ensuring dimensional accuracy and surface quality of the molds, meeting customers' quality requirements.

Quality Materials And Stable Processes: We pay attention to material selection and process optimization in the mold manufacturing process. We use high-quality mold materials and precisely control process parameters to provide reliable and high-performance mold products.

Strict Quality Control: We strictly adhere to quality control processes, conducting rigorous inspections and testing verification at every stage from mold design to manufacturing. We focus on details and precision, ensuring that every part of the mold conforms to design specifications and quality standards, providing reliable and stable mold products.

We work together with our top clients to create the best molds. Founded in 2009, Flourish Group specializes in product design, mold design, mold manufacturing, precision mold processing, medical accessory mold processing, injection molding, medical accessory injection molding, painting, screen printing, and assembly. To date, we have served clients from over 45 countries and completed more than 3,000 projects.

Mold Manufacturing and injection molding are common processes in the manufacturing industry used to produce various plastic products. Here is an introduction to the process:

| Steps | Descriptions |

| Mold Design | In the mold manufacturing and injection molding process, the first step is mold design. Designers use professional design software to create 3D models and structural designs based on the product requirements and specifications provided by the clients. The accuracy of mold design directly affects the quality and production efficiency of the final product. |

| Mold Manufacturing | After the mold design is completed, the next step is mold manufacturing. The manufacturing process typically includes the following steps |

| Material Preparation | Select suitable mold materials such as steel or aluminum and process them through cutting, forging, or casting. |

| Manufacturing | Precise machining of mold components using CNC machines, lathes, milling machines, etc., including hole machining, surface grinding, and wire cutting. |

| Assembly and Debugging | Assemble the machined mold components and perform debugging and adjustments to ensure the accuracy and reliability of the mold. |

| Surface Treatment | Apply surface treatments to the mold as required, such as rust-proof coating or surface polishing, to improve the mold's lifespan and appearance quality. |

| Injection Molding | After mold manufacturing is completed, the injection molding process begins. Injection molding involves injecting molten plastic material into the mold, which then cools and solidifies to obtain the molded plastic product. The steps of injection molding include |

| Plastic Material Preparation | Select suitable plastic raw materials based on product requirements and pre-processing them, such as drying and color mixing. |

| Injection Molding | Injecting the molten plastic material into the mold cavity through the injection system of the injection molding machine. |

| Cooling and Solidification | Allowing the plastic to cool and solidify inside the mold, forming the molded plastic product. |

| Mold Release | Once the plastic is fully cooled, open the mold and remove the molded plastic product. |

| Post-Processing | Performing post-processing techniques such as flash removal, trimming, polishing, painting, etc., to enhance the appearance and quality of the molded plastic product. |

The process of mold manufacturing and injection molding is a collaborative effort. Welcome to contact us for a quotation.

ISO International Quality Management System

Equipped with ISO 9001 certificate, we are able to support your OEM/ODM production.

Quality Control

We will check color, appearnce and tolerance by qulity control at every step during manufacturing process.

Low & High Volume Manufacturing

Besides high-volume production, we can also provide good solutions for your low-volume production (MOQ》1) with prototyping process.

Competitive Price

Our continuous investments in equipment and QC systems help us to get higher efficiency and quality which decrease reject ratio and increase market competitiveness in delivery qualified parts on time.

Reliability and Stability

Our 24 hours | 3 shifts production systems help your parts get into markets quickly and steadily.