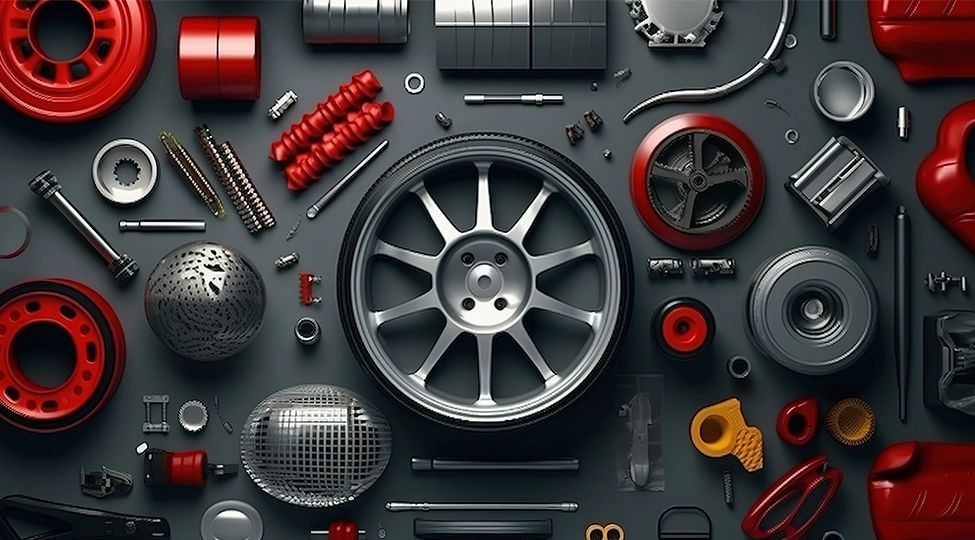

Flourish Legend excels in customized manufacturing of automotive and transportation industry components, including spare parts and hardware. With advanced processing equipment and a professional team, the company ensures high-quality and precision CNC machining services. Adapting to diverse client needs, timely delivery is guaranteed. Applications cover a wide range of industries, such as automotive spare parts, subway, high-speed rail, railway, marine, and shipping facilities. Flourish Legend offers personalized customization for crucial components, contributing to the advancement of the automotive and transportation sectors.

CNC machining is widely used in the automotive industry to produce various automotive parts. Below are some common automotive parts that are typically manufactured through custom CNC machining:

1. Engine Components: Including cylinder blocks, crankshafts, connecting rods, pistons, valves, and valve seats, etc.

2. Brake System Parts: Such as brake discs, brake calipers, brake pistons, etc.

3. Suspension System Parts: Including wheel bearings, control arms, suspension brackets, etc.

4. Transmission System Parts: Including gearbox housings, gears, transmission shafts, etc.

5. Vehicle Body Structure Parts: Such as door frames, roof supports, etc.

6. HVAC and Cooling System Parts: Such as air conditioning compressor housings, radiator brackets, etc.

7. Fuel System Parts: Such as fuel pump housings, fuel injectors, etc.

8. Electronic Control Unit (ECU) housings: Used to protect vehicle electronic controllers.

This is only a small portion of automotive parts, in reality, almost all automotive parts can be manufactured through CNC machining. CNC machining technology provides high precision and efficiency, making it a critical production process for the automotive manufacturing industry."

CNC machining is also widely used in the transportation industry to produce various critical components. Below are some common transportation industry parts typically manufactured through CNC machining:

| Industries | Parts |

| Railway Parts | Rails, turnouts, fasteners, rail connectors, etc., are used for railway track construction and maintenance. |

| Aviation Parts | Aircraft engine components, aerospace structures, aircraft landing gear parts, etc. |

| Marine Parts | Ship structural components, propellers, stern tubes, etc. |

| Public Transportation Vehicle Parts | Subway vehicle parts, bus body structural components, etc. |

| Bicycle And Motorcycle Parts | Frames, wheels, brake parts, etc. |

| Traffic Signal Parts | Used for road traffic signal control systems. |

| Traffic Signs And Road Sign Parts | Traffic sign brackets, road sign supports, etc. |

| Vehicle Engine And Motor Parts | Automotive engine housings, cylinder heads, etc. |

| Fuel And Hydraulic System Parts | Fuel pump housings, hydraulic valve bodies, etc. |

CNC machining technology ensures high precision and high-quality manufacturing of these parts, ensuring the reliability and safety of transportation vehicles. These parts are essential for the operation and maintenance of the transportation industry, and CNC machining provides efficient and precise production processes.

In the automotive and transportation industry, the production of parts involves various manufacturing processes to meet specific requirements. Below are some common manufacturing processes:

1. CNC Machining: Utilizing computer numerical control (CNC) machines, such as CNC lathes, CNC milling machines, CNC drilling machines, etc., for high-precision and efficient part manufacturing processes, including turning, milling, drilling, etc.

2. Die Casting: Used for producing complex-shaped metal parts by injecting molten metal into molds and cooling to solidify. This method including sheet metal press die casting is commonly used for manufacturing parts like engine cylinder blocks, crankshafts, etc.

3. Injection Molding: Suitable for machining plastic parts by injecting melted plastic into molds to form the desired shapes.

4. Sheet Metal Processing: Utilizing laser cutting, bending, and welding techniques for precision manufacturing of sheet metal parts, such as car body panels.

These are just some common manufacturing processes. In reality, the production of automotive and transportation industry parts may involve other specific processes, depending on the design requirements and materials used. The application of these manufacturing processes ensures high-quality and high-performance production of parts in the automotive and transportation industries.

Automotive and transportation industry parts are commonly made from various materials, selected based on specific performance, strength, durability, and cost requirements. Below are common materials used for these parts:

| Material | Industry Parts |

| Steel | Manufacturing many structural parts, such as frames, engine cylinder blocks, crankshafts, suspension system parts, etc. Steel is known for its high strength and excellent durability. |

| Aluminum alloy | Manufacturing body structural components, wheels, brake system parts, etc. Aluminum alloy is relatively lightweight and contributes to improved fuel efficiency by reducing overall vehicle weight. |

| Plastic | Producing interior parts, exterior body components, sensor housings, etc. Plastic materials including CNC machining ABS are lightweight, cost-effective, and have good corrosion resistance. |

| Rubber | Manufacturing rubber seals, hoses, suspension system parts, etc. Rubber materials offer excellent elasticity and sealing properties. |

| Cast Iron | Engine cylinder blocks, brake system components, etc. Cast iron provides high strength and good wear resistance. |

| Copper Alloy | Manufacturing transmission system parts, electrical conductive components, etc. Copper alloys possess good thermal and electrical conductivity. |

| Carbon Fiber | Structural components of high-performance vehicles and racing cars. Carbon fiber is known for its high strength and lightweight properties. |

| Stainless Steel | Parts requiring high corrosion resistance, such as exhaust pipes, intake pipes, etc. |

These are some of the commonly used materials for automotive and transportation industry parts. Each material has its specific advantages and suitable applications, and the selection of appropriate materials ensures the performance and quality of the parts.

When CNC machining automotive and transportation industry parts, it is crucial to consider the following important points:

| Processes | Descriptions |

| Material Selection | Choosing the right materials is essential, considering the part's functionality and performance requirements, including strength, wear resistance, and corrosion resistance. |

| Machining Processes | Selecting appropriate CNC machining processes such as milling, turning, drilling, etc., based on the part's shape and requirements. |

| Process Sequencing | Properly planning the sequence of CNC machining to avoid conflicts and minimize time wastage. |

| Machining Precision | Ensuring CNC machining precision meets the part's design specifications, preventing dimensional deviations that may hinder proper assembly. |

| Tool Selection | Choosing suitable tools to ensure their quality and cutting performance, thereby ensuring high-quality machining. |

| Tool Wear Monitoring | Regularly inspecting and replacing heavily worn tools to maintain CNC machining stability and efficiency. |

| Cleaning And Coolant Management | Keeping the machining equipment and work area clean, promptly removing chips and waste, and ensuring sufficient and appropriate coolant. |

| Adjusting Machining Parameters | Tailoring machining parameters according to different materials and part requirements to achieve optimal machining results. |

| Quality Control | Implementing strict quality control, including first-piece inspection and in-process checks, to ensure each part meets specifications and standards. |

| Safety Measures | Complying with safety regulations to safeguard employee well-being and prevent accidents. |

By adhering to these guidelines, CNC machining of automotive and transportation industry parts can guarantee high-quality, high-performance, and stable components, meeting the demanding requirements of the automotive sector for parts.

ISO International Quality Management System

Equipped with ISO 9001 certificate, we are able to support your OEM/ODM production.

Quality Control

We will check color, appearnce and tolerance by qulity control at every step during manufacturing process.

Low & High Volume Manufacturing

Besides high-volume production, we can also provide good solutions for your low-volume production (MOQ》1) with prototyping process.

Competitive Price

Our continuous investments in equipment and QC systems help us to get higher efficiency and quality which decrease reject ratio and increase market competitiveness in delivery qualified parts on time.

Reliability and Stability

Our 24 hours | 3 shifts production systems help your parts get into markets quickly and steadily.